Overview

Reliable Ignition. Anytime. Anywhere.

Ensuring safe and efficient pilot ignition in flare systems is critical for both operational reliability and environmental compliance. The John Zink Flame Front Generator (FFG) Pilot Ignition System delivers a proven, remote ignition solution that has been trusted for decades.

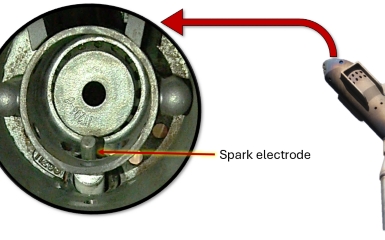

By combining ignition fuel and compressed air at a mixing tee, the FFG system generates a controlled flame front that travels through an ignition line to the pilot tip, ensuring consistent ignition without the need for direct access to the flare.

Designed for flexibility and safety, the FFG system can be installed over 1,000 feet away from the pilot, providing remote operation and easy maintenance at grade. Available in both manual and automatic configurations, the FFG ignition process can be powered by either a line-powered transformer (standard) or a piezoelectric unit in rare, manual only applications. .

With local indicator lights and remote alarm contacts, operators can monitor ignition status in real time, reducing unplanned downtime and maintenance risks. The FFG system can be serviced and maintained without shutting down the flare, making it an efficient, cost-effective solution for flare pilot ignition.